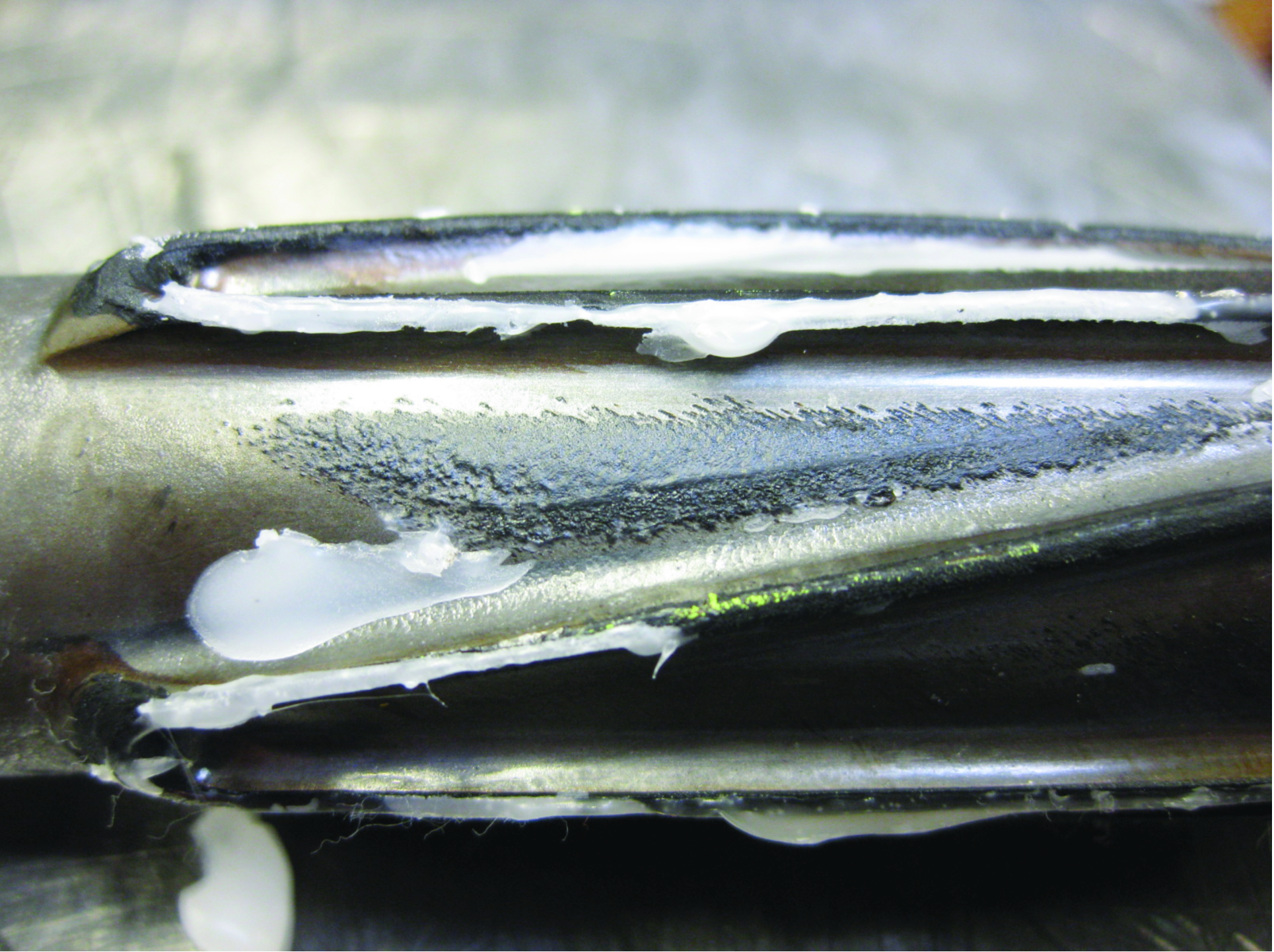

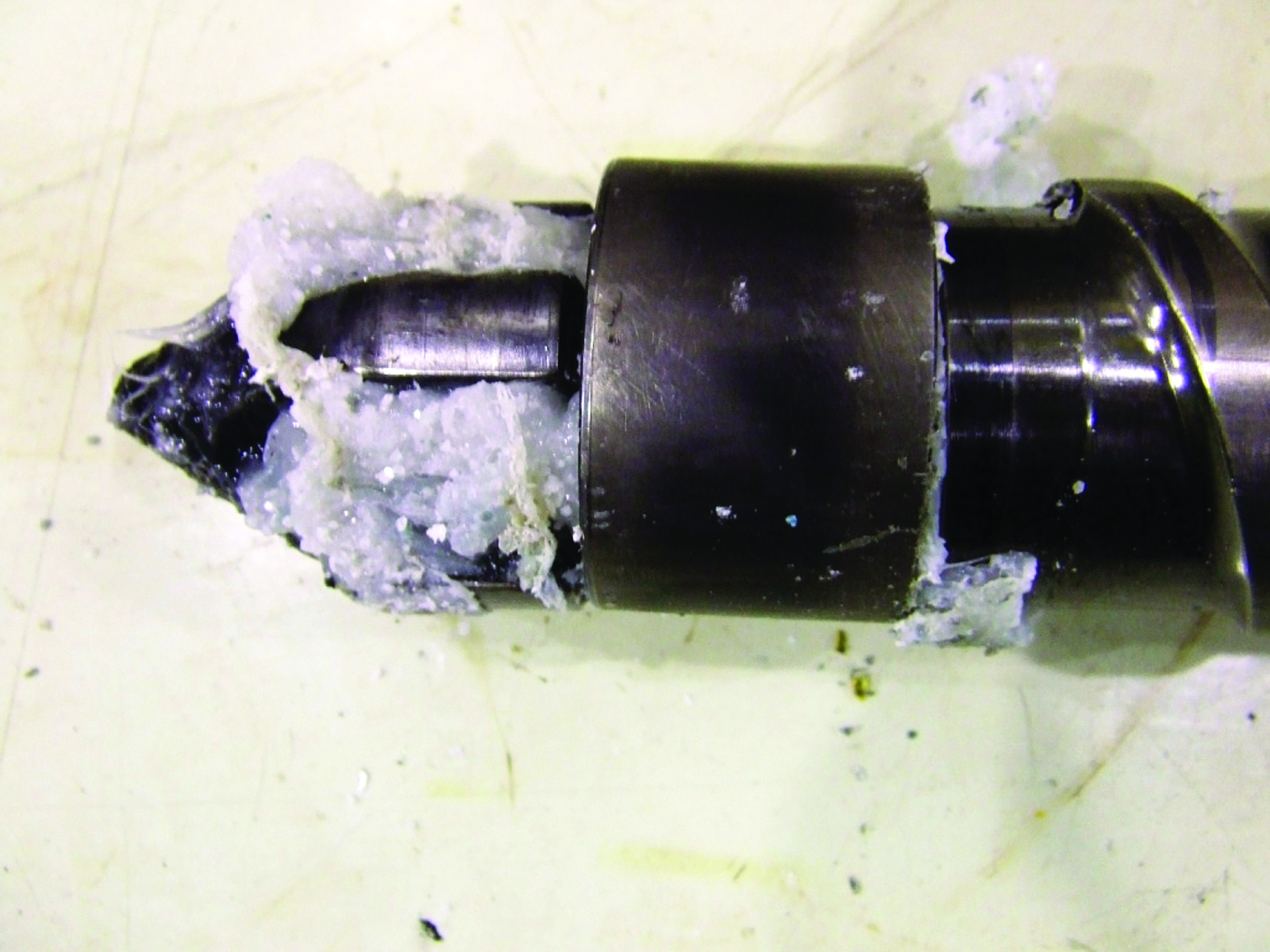

Das neue Reinigungscompound BLITZ PURGE HR setzt durch seine universelle Einsetzbarkeit bei allen Materialien, Temperaturen und nun auch für Heißkanälen, neue Maßstäbe bei Materialwechseln. Seine einzigartige Reinigungswirkung entfernt nun nicht nur Verbrennungen von Schnecken, sondern auch aus Heißkanälen mit geringen Querschnitten. Eine Grundreinigung Ihrer Heißkanäle erspart Ihnen künftig viele Wartungskosten und verkürzt i.d.R. auch alle folgenden Wechsel mit Naturmaterial, weil sich Material oder Farbe nicht mehr an rauen Oberflächen von degradiertem Materialrückständen ablagern kann. So muss bei den folgenden Wechseln weder Material noch Farbe immer wieder aufs Neue aus diesen Haltepunkten herausgespült werden.

Durch die mechanische, feine Polierwirkung kommt BLITZ PURGE HR komplett ohne chemische Zusätze aus und kann auch für Artikel im Kosmetik- oder Nahrungsbereich verwendet werden. Alle Inhaltsstoffe sind als generell sicher eingestufte Stoffe gelistet, weshalb es geruchlos und unbedenklich für Anwender ist.

Die Handhabung ist kinderleicht. Anwender müssen keinerlei Änderungen von Temperaturen oder sonstigen Einstellungen vornehmen und können es bei allen Materialien universell einsetzen.

Es gibt lediglich drei kleine Einschränkungen beim Einsatz:

BLITZ PURGE HR kann nicht durch Siebe oder Filterdüsen dosiert werden. Sollte dieses aber einmal übersehen werden kann eine Blockade der Filterdüse i.d.R. ohne Beschädigungen wieder leicht entfernt werden.

Heißkanalreinigungen dürfen nur durch geöffnete Werkzeuge durchgeführt werden.

+49 30 85 72 79 44

+49 30 85 72 79 44 info@knabepolytec.de

info@knabepolytec.de

Kalckreuthstraße 6, 10777 Berlin

Kalckreuthstraße 6, 10777 Berlin